Remember James Harvey Leighton? Marble collectors everywhere and those who just have a love of marble history remember Leighton for his 1891 patent for the “manufacture of glass spheres”. This was the first U.S. patent issued to make toy glass marbles by machine instead of by hand.

Double Dipping?

As described in our recent post Sand: Another Four Letter Word? Leighton is both famous and infamous for his association with Iowa City Flint Glass starting in the late 1800s. But there is also a link between Leighton and Samuel C. Dyke who manufactured the first mass-produced toy marbles in America. Dyke made clay marbles at his factory which opened in Akron, Ohio, in 1884. But then in 1890 Dyke hired master glass maker James Leighton to train workers in making glass marbles. This means that Leighton both held his own patent and worked for Dyke in Akron to produce glass marbles.

Some enthusiasts do not believe that Iowa City Flint Glass produced novelty glass items like canes, batons and marbles because of the poor quality glass used. But there is evidence that all of these novelties were made there. Let’s start with what we can learn about batons and canes from Miriam Righter’s book Iowa City Glass.

Iowa City Batons & Canes

Righter has two black-and-white photographs in her book on Iowa City Glass on page 53, Plates 35 and 36. These images are of the same cane: one is a blow-up. She also has the name of the individual who evidently owned the cane. This is what Righter tells us about the cane: “Plate 35. Iowa City blown-glass cane, with hollow nob” and “Plate 36. Enlarged nob and upper portion of glass cane….”

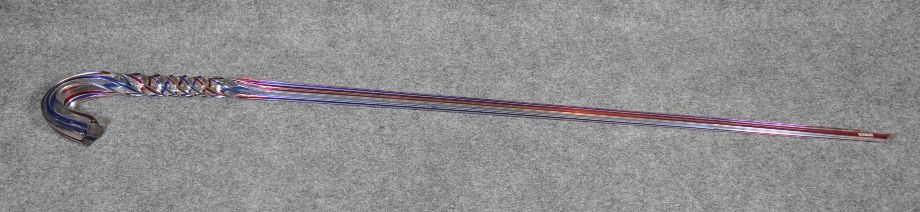

The photograph above is of a baton and we will explain in a moment. However, it looks remarkably like the one in the Righter book![1]

Why Were Canes Ever Made at Glasshouses?

There is a long history of workers in glass factories making canes, batons, and marbles at the end of a shift. We won’t delve into this background. Most of the stories of glass canes that we know of date to the 19th and into the mid-19th century. Iowa City certainly got a head start!

Nancy Magrath has written a comprehensive overview on the subject of glass canes in her blog post “When the glass workers marched on parade”. The post was published by Corning Museum of Glass.[17] Many of us are familiar with Dean Six’s book West Virginia Glass Towns (Charleston, WV: Quarrier Press, 2012). Well, Six has photographs of glassworks canes in parades and some information about them. Check pages 8, 107, 108, and 137.

Magrath’s Opinion

“Glassworkers have a long tradition of making whimsies—fanciful objects to show off their creativity, skill, and humor. These were personal items made during work breaks and at the end of long, hot days at the factory….Glassworkers made [glass] chains, sock darners, rolling pins, paperweights, animals….

Some glass canes were 6 to 8 feet long and were topped by objects such as fish bowls, goblets, and musical instruments to display the glassworker’s special skill. …” Canes were given to family members and they were sold. “Canes were also bartered; local bars often had a collection of canes displayed on their wall in exchange for drinks.”

And canes were featured whenever the glass workers went on parade for the company. [2]

Magrath also tells us that canes were made in two basic forms: hollow blown glass, like this one from Iowa Glass, and solid worked glass. Blown ones were sometimes called batons. Some of these batons, like this one, were striped while others were filled with beverages, candies, and sand. A skilled worker could make a cane in about 30 minutes!

Hollow glass canes, like the one shown from Iowa City above, are free blown[3], pulled and stretched. It is made solely by inflation using a blowpipe. It could be “blown” by two workers or through some type orifice and manipulated with other types of tools.

Looking Back; Looking Forward

We will look at the chemistry of canes in a moment. But based on what you know now about Iowa City that hot summer of 1881, do you find it probable that the 150 workers, to include Leighton, had the time and energy, or interest, to make any kind of whimsy at the end of the day? One thing in Magrath’s blog does ring true: the part about bartering for beer! If canes were bartered in bars in Iowa City then we wonder where those novelties are today.

Hot All Over!

Hot All Over!

We knew enough about glass to understand that making glass canes would take skill and care. But canes, it seems to us, would require especially good quality glass to include glass silica or sand. If for no other reason quality would be needed because of the glass’ compressive and tensile stress.

We knew that in Iowa City the glass in the patterned dishes was often not top quality. At times there was a green tint to the glass; some broke easily; and some even “exploded” in shops and homes.

We wondered how such glass could even hold up to the stress of making a cane. So, we turned to an expert to try and learn if it was possible to make stressed canes from poor quality glass.

Awhile back we bought the twisted and fused solid glass cane pictured above at an antique shop in Auburn, Alabama. The tip was chipped, but we have found only two glass canes for sale in some twenty years of searching. The price was right and so we bought it.

While we knew almost nothing about the chipped glass cane at the time, we did know someone whom we could speak to about fixing it. When we got home we made an appointment and took the cane to Matthew Fenske, Glass Artist & Owner of Island Fire Glass Art Gallery & Espresso Bar, Saltaire, Alabama.[4]

Matt kept the cane for some time and then he called us to say that he was hesitant to attempt any repair. He explained that our solid cane, as you can see in the photographs, is made of two fused rods of different colors twisted together and that when heated, depending on a number of other factors including the glass’ coefficient of expansion (COE) the entire cane would have to be heated at the same time and to the same COE rather than heating the glass in only one spot.

He could not heat the two rods because it would require such a high temperature. So we displayed the cane with our marbles and marble-related artifacts and just enjoy seeing it every day.

This project confirmed for us how complex cane-making could be. When a person admires a glass cane it is not easy to comprehend just how difficult each one may be to make.

When we became aware of Iowa City glass canes in the fall of 2023 Joanne again called Matt to ask him some generalized ideas about how solid and hollow glass canes are made.

Making Hot Canes

Depending on its total length, a solid glass cane cannot be heated in only one spot. The entire length of the cane, to include any crook or knob, must be heated at the same time despite the fact that the COE of the twisted and fused glass may be different. The tension of the cold and hot spots will exceed the strength of the glass in the cane.

As noted, COE is a measure of how much a material expands or contracts with changes in temperature. In the context of glass canes, COE is used to describe the compatibility of different types of glass. Glass canes with the same COE can be fused together without cracking or breaking. COE 90 and COE 96 are two common types of glass canes used in glass art.

Notice how the crook in our handle tapers toward the end of the two rods. Referring again to our cane, should Matt have attempted a repair by melting the tip then part or even all of the cane may have splintered.

Molds, Paddles & Hollow Canes

This is another type of glass cane that might have been made by Iowa City Glass. While squared it has the same characteristics as a twisted cane. It was squared either by hand or by working using paddles. It may also have been squared by using a squared mold.

This is one of the more beautiful glass canes that we have seen anywhere! It is both beautiful and complex. This photograph is from the collection held at the State Historical Museum of Iowa, Des Moines. The accession number for this lot is 2000.079.002 and this is the description: “Cane, clear glass shaped by hand, square solid shaft with crook handle, slightly molded, 5 inch long twisted section below handle, red and blue threads through the handle and shaft, 35.5 X 4 X 1 inches. Attributed to the Iowa City Flint Glass Manufacturing Company, cira 1880-1882.”[5]

While looking at this cane think back to the time when Iowa City Glass was running. Workers either poorly trained or without commitment to the project. Rumors of sabotage. Cut and run to the bars when the whistle blows. Glass quality which has been downgraded by the glass industry. Exploding plates! Higher freight cost because sand has to be shipped in to make the glass.

And perhaps worst of all: poor glass or silica sand as a base.

Circumstantial Probabilities

And yet, and in fact because of, all of the history, mystery, and secrets surrounding the Iowa City works, we do believe that the canes, like the marbles, were made in Iowa City 1880 – 1882. There is simply too much circumstantial evidence to ignore.

Just as examples:

- There is a long list of 58 contributors to the Righter project on the “Acknowledgements” page of her book as well as these notations: these individuals made contributions to her book “…through loan of specimens for photographing, permitting the photographer to come into their homes, searching through family records for needed information, answering innumerable questions….”

- There are at least hundreds of individuals who own Iowa City glassware in Eastern Iowa and well beyond.

- Patterned flint glass sherds have been found and dug on the site of the old glasshouse. [6]

- Even taking the whole situation at Iowa City Glass into account, there are hundreds or thousands of pieces of Frosted Stork, Elaine, dog mugs, elephant goblets, Alhambra, and so much more dressing up collection cabinets all over the United States. How can we possibly say that there are no glass marbles and canes out there and no more undiscovered or unattributed?

Iowa City Glass Marbles[7]

We have spent a lot of time on the Iowa City project and have studied a number of photographs of their marbles. In fact we have studied photographs of every Iowa City marble and cane that we can find. We have also studied what little there is in the online media about marbles being made there.

While it seems that over the last few years there is an increasing amount of acceptance of the fact that, as unlikely as it seems, swirl marbles, canes, and even sulfides were made there. European collectors, including those in Germany, are much more accepting of the American mid-western marbles.

But here in the U.S., there continue to be naysayers online. This is their general drift: “I have spent hundreds of hours on this topic and Iowa City did not make any marbles.” By extension we would imagine that they did not make canes, either? “The marbles in the [Miriam] Richter book are German.”

We have every respect for anyone who commits to such a project. It’s difficult. Often unrewarding. But when online please give your readers at least samples from your research. What evidence do you have for your premises?

Well, It Looks German

We agree. But, again deferring to propositional logic, exactly what should the first marbles and glass canes made west of the Mississippi River look like. Using “the marbles look German” as another strong opening, follow up and tell your readers exactly what else they should look like.

Close & Bar the Door

We leave Iowa City behind. Still, if you do have relevant information about glass canes and marbles made there, or if you have photographs of marbles or canes with their history then we would love to share them with our readers.

And, always, if you do want to build a logical proposition about why the marble and the canes in this post cannot be American then please do tell us.

Otherwise we close the door on another historical and mysterious chapter in American marble making. And, yes, there are still many glass secrets all across eastern Iowa which remain unsolved.

References

- This photograph is from the collection held at the State Historical Museum of Iowa, Des Moines. The accession number for this lot is 2000.079.001 and this is the description with the cane-baton: “Cane clear blown glass with hollow bulbous knob and tapering hollow shaft, threads of white, red, and blue spiral around shaft, 30.5 X 2 inches. Attributed to the Iowa City Flint Glass Manufacturing Company, cira 1880-1882. 39.5”: long.” There is also a notation regarding where and when the cane was purchased. Courtesy of the State Historical Museum of Iowa. Special thanks to Kay Coats, Collections Coordinator, State Historical Museum of Iowa @ https://iowa.minisisinc.com/scripts/mwimain.dll/126481118/3/0?SEARCH&DATABASE=COLLECTIONS&SIMPLE_EXP=Y&ERRMSG=[IOWA_root]no-record-collections.html/ (11/21/2023) ↑

- https://blog.cmog.org/2018/09/25/when-the-glass-workers-marched/ 12/1/2023 ↑

- https://www.thehouseofglassinc.com/dictionary.htm (11/10/2023). This website is called simply “Glass Terminology & Facts”. It is an excellent place to learn more about glass working in short and precise terms. ↑

- https://www.islandfireglass.com/ (11/10/2023); twistedcane.com (11/10/2023); https://www.pinterest.com/DLArtGlass/ (11/10/2023). Read all about Matt at https://thesecretlifeofmarbles.com/the-art-of-makng-marbles-in-the-21st-century/ (11/10/2023) Joanne spoke with Matt on November 6, 2023. ↑

- There is also a notation regarding where and when the cane was purchased by the State of Iowa. Courtesy of the State Historical Museum of Iowa. Special thanks to Kay Coats, Collections Coordinator, State Historical Museum of Iowa @ https://iowa.minisisinc.com/scripts/mwimain.dll/126481118/3/0?SEARCH&DATABASE=COLLECTIONS&SIMPLE_EXP=Y&ERRMSG=[IOWA_root]no-record-collections.html/ (11/21/2023)

- No contributor is listed and we are left to wonder if Righter donated these sherds to the Museum. ↑

- This gorgeous marble is in the collection held at the State Historical Museum of Iowa, Des Moines. The accession number for this lot is 1607 and this is the description: “Marble, large glass Onionskin marble, inner swirl of opaque green, white, and red design, cased in clear glass, 2 inches in diameter, several chips. Attributed to the Iowa City Flint Glass Manufacturing Company, circa 1880 – 1882.” Courtesy of the State Historical Museum of Iowa. Special thanks to Kay Coats, Collections Coordinator, State Historical Museum of Iowa @ https://iowa.minisisinc.com/scripts/mwimain.dll/126481118/3/0?SEARCH&DATABASE=COLLECTIONS&SIMPLE_EXP=Y&ERRMSG=[IOWA_root]no-record-collections.html/ (11/21/2023) ↑